Pole120

Addicted CEG'er

I'm sorry it's taken me so long to find time but I've finally found time to make real updates.

As stated earlier I got a Black E0 from Blu_fuz. The car had a rod knock and he and another member had begun to part the car out. Then I came along and took the car as it sat, It had no suspension or wheels so I brought what we needed, set her on the ground and I puller her home. Initially I had intended to use the car to build myself a new DD, so after pulled the blown stock unit, I dropped in an SE motor I had laying around, added a COP swap and built trans with headers and spec stage 1. Not long after I dropped the motor in I got a new shop with heat, so we moved the car out there and I continued assembly there, cleaning the interior, repairing wiring and replacing all the components that were missing with items from my stock of spares. As you can see the interior was a mess. All of the seats were damaged and the front doors gutted. I cleaned the interior up, installed a dash and harness and finished engine assembly. We fired the car up after just a couple days and once I got it back to running condition I decided given the car's overall minimal rust that it would make a good candidate for the RWD conversion project's final home, and with that I decided to pull the new heart right back out.

The car as I towed it home:

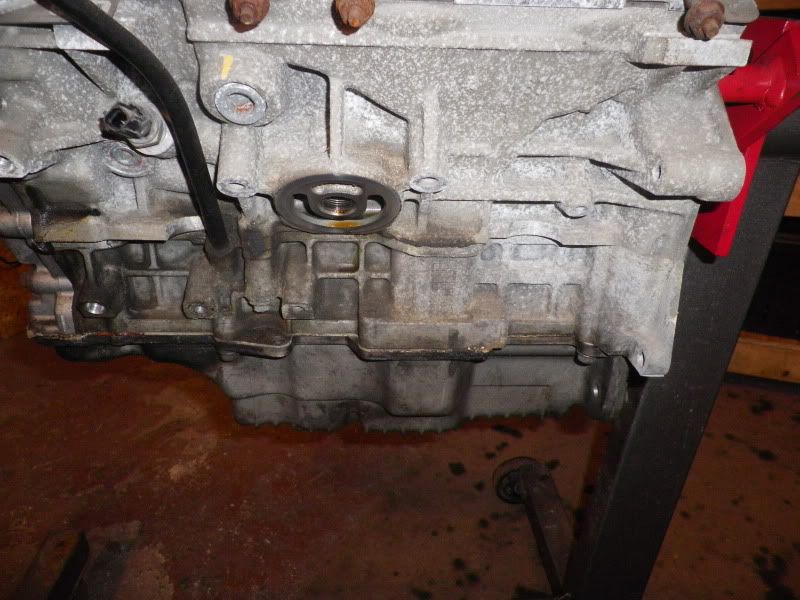

Engine 1 out and engine 2 in:

Car as moved to new shop:

Tail lights installed and trunk swapped for non-wing:

And lastly the interior. There was a lot of work involved in fixing the wiring that was hacked up for things like part removal and an alarm and stereo install at one point, but it has all been repaired and/or replaced thanks to the spare harnesses I have at the shop.

As stated earlier I got a Black E0 from Blu_fuz. The car had a rod knock and he and another member had begun to part the car out. Then I came along and took the car as it sat, It had no suspension or wheels so I brought what we needed, set her on the ground and I puller her home. Initially I had intended to use the car to build myself a new DD, so after pulled the blown stock unit, I dropped in an SE motor I had laying around, added a COP swap and built trans with headers and spec stage 1. Not long after I dropped the motor in I got a new shop with heat, so we moved the car out there and I continued assembly there, cleaning the interior, repairing wiring and replacing all the components that were missing with items from my stock of spares. As you can see the interior was a mess. All of the seats were damaged and the front doors gutted. I cleaned the interior up, installed a dash and harness and finished engine assembly. We fired the car up after just a couple days and once I got it back to running condition I decided given the car's overall minimal rust that it would make a good candidate for the RWD conversion project's final home, and with that I decided to pull the new heart right back out.

The car as I towed it home:

Engine 1 out and engine 2 in:

Car as moved to new shop:

Tail lights installed and trunk swapped for non-wing:

And lastly the interior. There was a lot of work involved in fixing the wiring that was hacked up for things like part removal and an alarm and stereo install at one point, but it has all been repaired and/or replaced thanks to the spare harnesses I have at the shop.