SoopaCooga

Veteran CEG'er

$75 plus shipping from team ford parts.

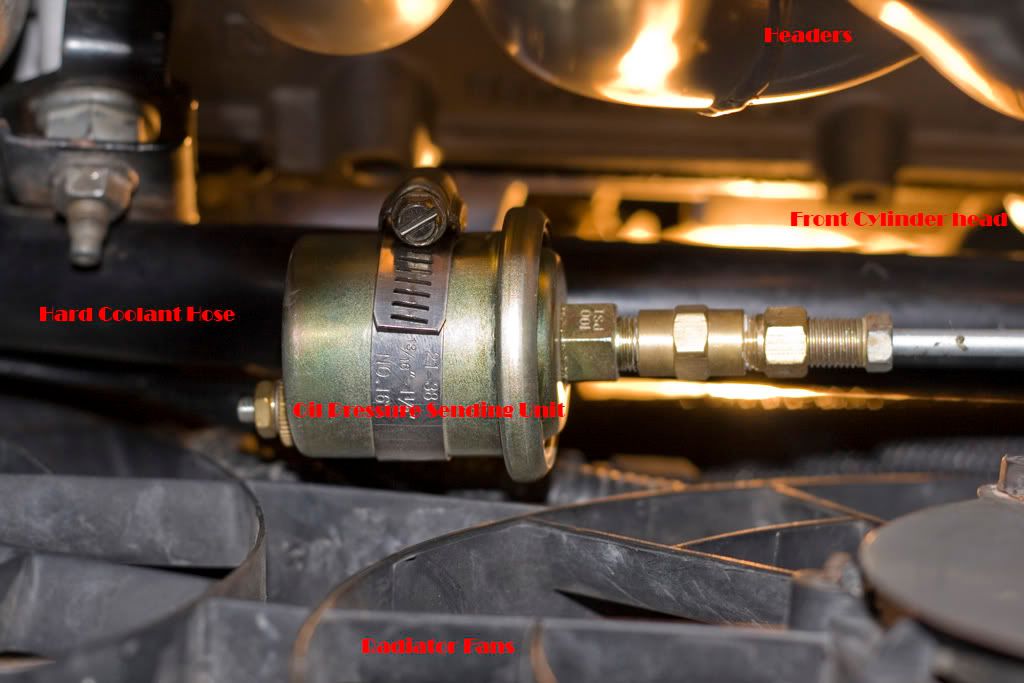

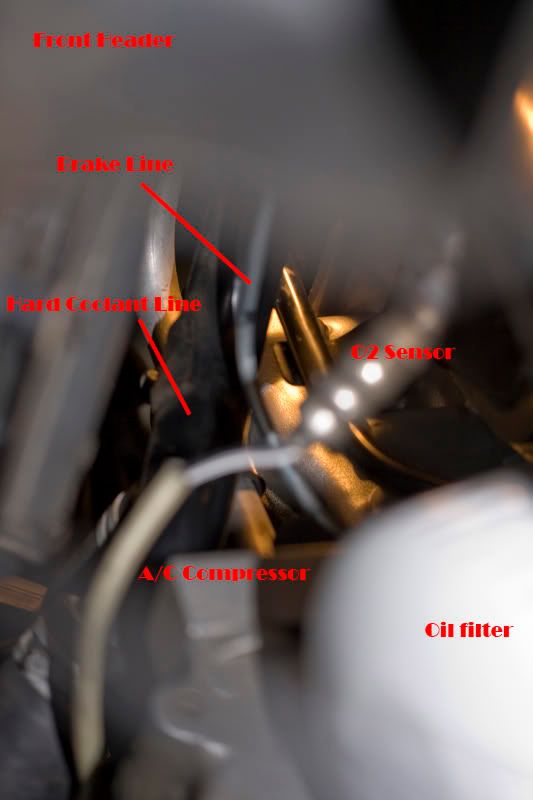

but you don't have to go that way. but it allows for two senors to be installed or a oil cooler added. you can use a larger oil filter and will not get oil all over the exhaust manifold when you change the oil. a win all around.

Well, crap, what's up with that? Bill J sold me "the last one" last month for $85 plus shipping.

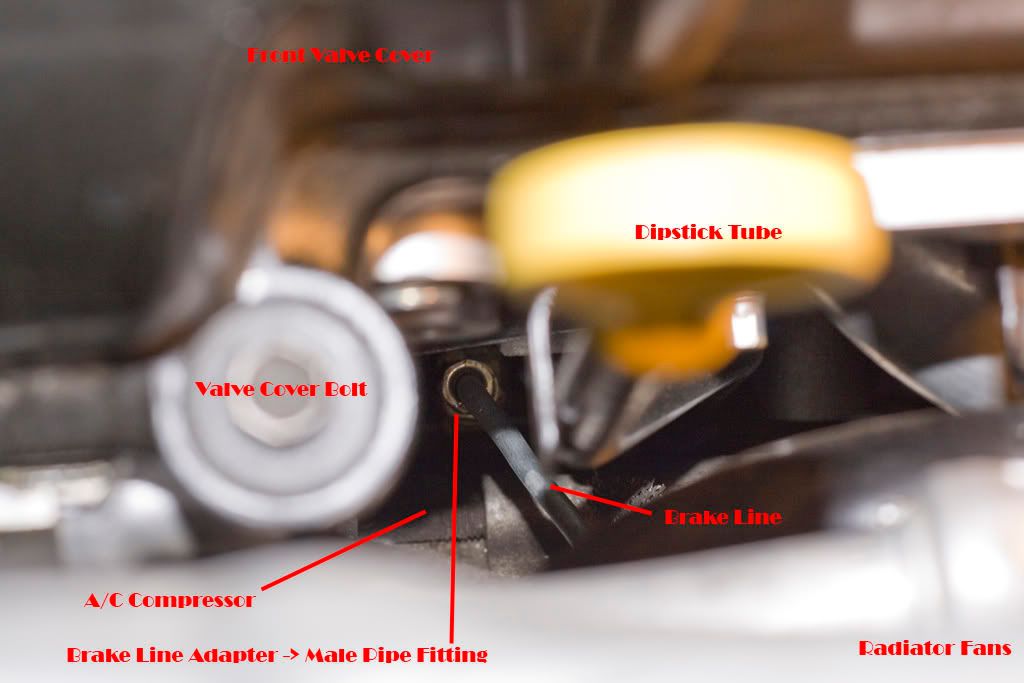

BTW, does an Autometer mechanical gauge reach from the dash to the spot where you mounted yours?