Stuart-Grant

CEG'er

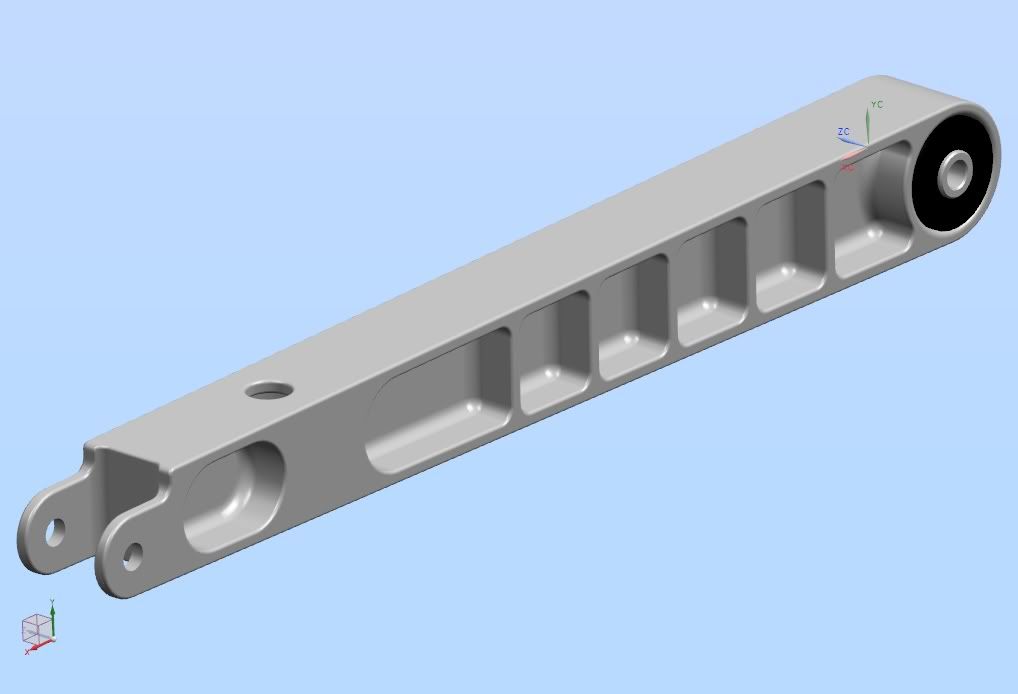

Alright, anyone who surfs NECO has probably seen my development thread on some billet rear lateral control arms.

For those who haven't I'll give a brief break down.

Material will be 4140 de-carb free hardened steel (30 Rockwell C)

Bushing will be Shore 80A Polyurethane drilled out for a pressed in sleeve and will be externally greaseable with a grease reservior.

Arm will weigh about 15 lbs each, though this is still subject to change since the final design revision is not yet complete.

Arms will be prepared for full winter use. 7 step zinc phosphate coating followed by Zinc rich primer powder, followed by super durable black powder coat. This level of coating is usually seen on military parts only, in fact I'll be using MIL specs to call out the finish!

Will come with class 12.9 hardware.

To express interest Please follow this link to NECO and vote in the poll. Please select all options you're willing to pay for. Obviously I'll be trying to get these as low as possible, but I am not cutting any corners on this project.

I anticipate having the first prototype units on hand by the new year and hopefuly I can do a group buy some time in spring. I just want to have an idea on numbers to give the machine shop for estimating purposes.

For those who haven't I'll give a brief break down.

Material will be 4140 de-carb free hardened steel (30 Rockwell C)

Bushing will be Shore 80A Polyurethane drilled out for a pressed in sleeve and will be externally greaseable with a grease reservior.

Arm will weigh about 15 lbs each, though this is still subject to change since the final design revision is not yet complete.

Arms will be prepared for full winter use. 7 step zinc phosphate coating followed by Zinc rich primer powder, followed by super durable black powder coat. This level of coating is usually seen on military parts only, in fact I'll be using MIL specs to call out the finish!

Will come with class 12.9 hardware.

To express interest Please follow this link to NECO and vote in the poll. Please select all options you're willing to pay for. Obviously I'll be trying to get these as low as possible, but I am not cutting any corners on this project.

I anticipate having the first prototype units on hand by the new year and hopefuly I can do a group buy some time in spring. I just want to have an idea on numbers to give the machine shop for estimating purposes.