Big Jim

Hard-core CEG'er

Why not use a slide hammer? That's how I've always removed pilot bushings.

are we trying to say the grease/hydraulic method of getting the bushing out doesn't actually work?

don't the contours use a pilot bearing for the MTX input shaft? if so wouldn't the bushing need to come out so that the pilot bearing could go back?

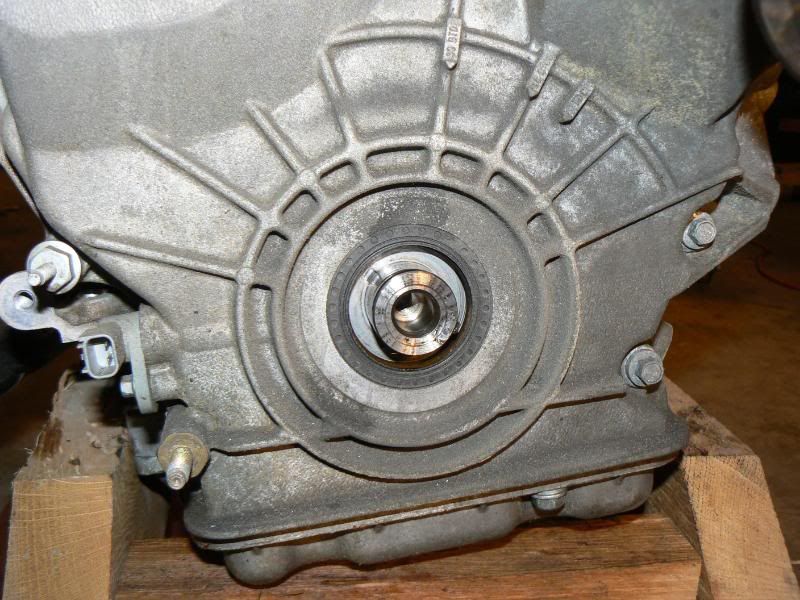

Now there are finally some pictures for future reference for anyone looking to remove the crank pulley and damper.

I used two bolts through the flywheel to hold everything still.

Notice that the pulley has been cut off between the pulley and damper.

With the flywheel chocked, I used a 1" wrench with a pipe slid over it for added leverage. With a decent amount of persuasion it finally broke free and spun off to reveal the damper bolt.

Remove that bolt and attach the pulley puller

Back off the pulley and then it's done.

Hahhaa, well you and I are just learning a bunch from each other here aren't we. Thanks for the info, and yeah...that stupid little piece comes right out with an air hammer and a little assistance from the vise grips in your other hand.haha, the bushing comes out that easy? awesome

and the taurus pan fits the 'tour dude. you can drill the two holes pretty easy, I also hear some guys don't even bother with them.

....

Ummm, have you taken the oil pan off yet? Depending what you got that 3L from, you might have to swap the oil pan and oil pick up tube from the Contour engine. You might get into another surprise......