CrazyTalkSVT

Veteran CEG'er

The title suggests following suit to Project - Face Lift - with the body modifications, which this thread eventually will. However, instead of removing things I'm actually adding here and there so the title "Project - Breast Implants - probably would be a better fit, but I didn't want to give the youngsters the wrong idea.

So for comparison sake here is a photo that Redlineracer12 took a couple years ago (minus the Mondeo front end). Tony, you rock!

There are certain (small) things that have always bugged me and as time has gone on they have become more annoying to me. I have highlighted them in red...be kind, my Paint skills are not the greatest.

The obvious is the jackpoint covers. Which I think the majority of us all kind of say "ish" to. The other is the meet up point to the rocker. Sometimes it looks ok, but mostly they sag in the front and/or the rear. The gap isn't very consistent and alot of the time they develop waves where they spread away from the rocker.

Then there is the kick-up in the center of the side skirts. I liked it at first. Then I started feeling like, "well the doors don't kick up, the window line doesn't kick up...for the most part the bottom of the car is straight across...why did Ford build in a kick-up....ughhhh!!" So I have to do something about that as well.

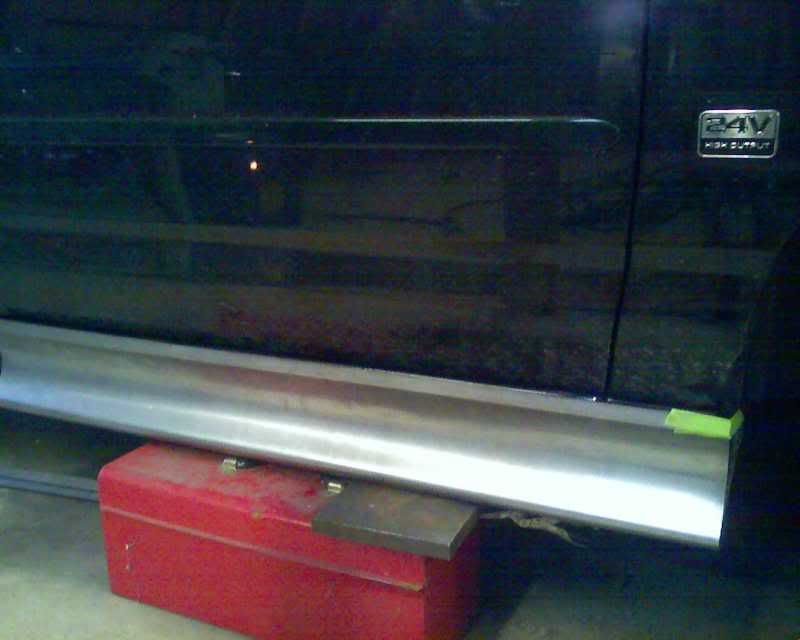

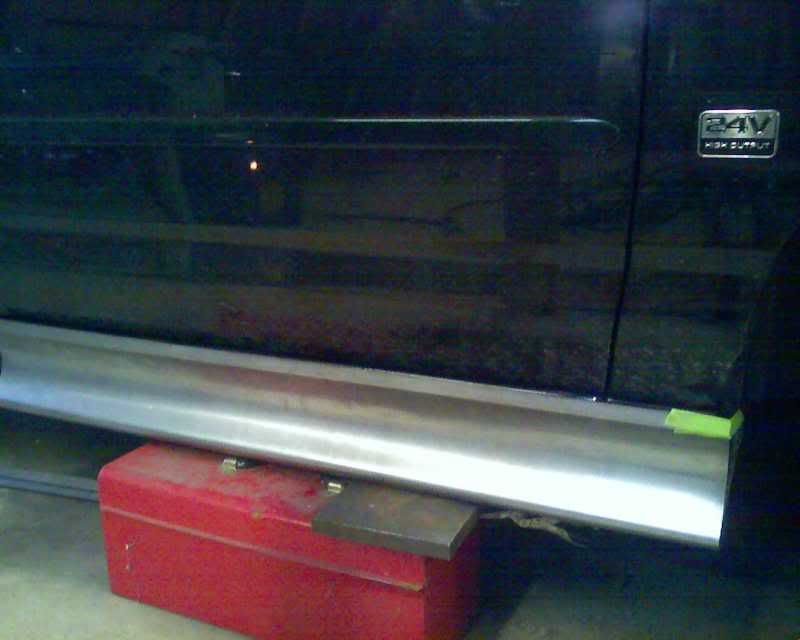

So this is the start

This is one of the pieces propped up and just taped to the stock skirt to get an idea (cell photo).

It's a start. Have a good day guys. I'll update when I can.

So for comparison sake here is a photo that Redlineracer12 took a couple years ago (minus the Mondeo front end). Tony, you rock!

There are certain (small) things that have always bugged me and as time has gone on they have become more annoying to me. I have highlighted them in red...be kind, my Paint skills are not the greatest.

The obvious is the jackpoint covers. Which I think the majority of us all kind of say "ish" to. The other is the meet up point to the rocker. Sometimes it looks ok, but mostly they sag in the front and/or the rear. The gap isn't very consistent and alot of the time they develop waves where they spread away from the rocker.

Then there is the kick-up in the center of the side skirts. I liked it at first. Then I started feeling like, "well the doors don't kick up, the window line doesn't kick up...for the most part the bottom of the car is straight across...why did Ford build in a kick-up....ughhhh!!" So I have to do something about that as well.

So this is the start

This is one of the pieces propped up and just taped to the stock skirt to get an idea (cell photo).

It's a start. Have a good day guys. I'll update when I can.