Pole120

Addicted CEG'er

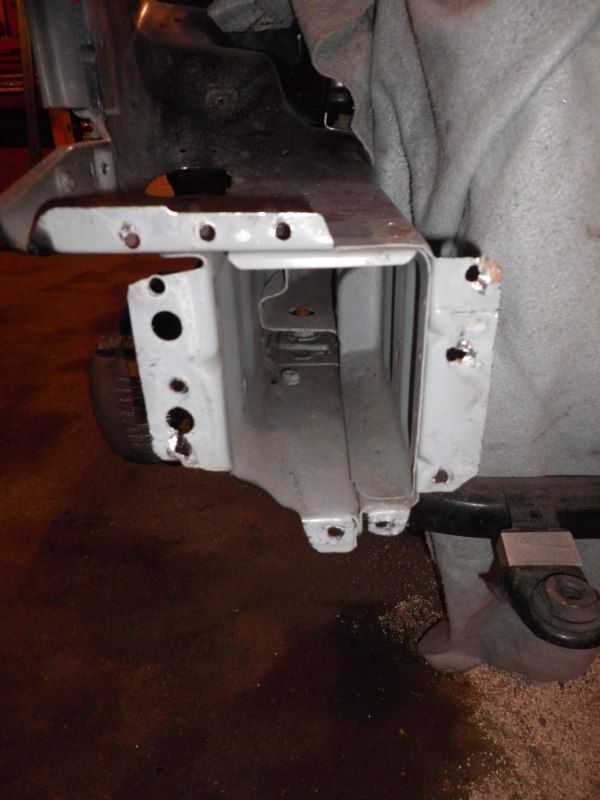

Well I have everything except the 1" OD tube for the new core support, and that won't be in until Friday now. I have what I need to get the crash bar rebuilt and connect the frame horns, as well as to finish the engine and trans mounts so that will be this week's focus.