CSVT#49

Addicted CEG'er

So guys I'm tittering on edge on what I should do on this. Here are my options...

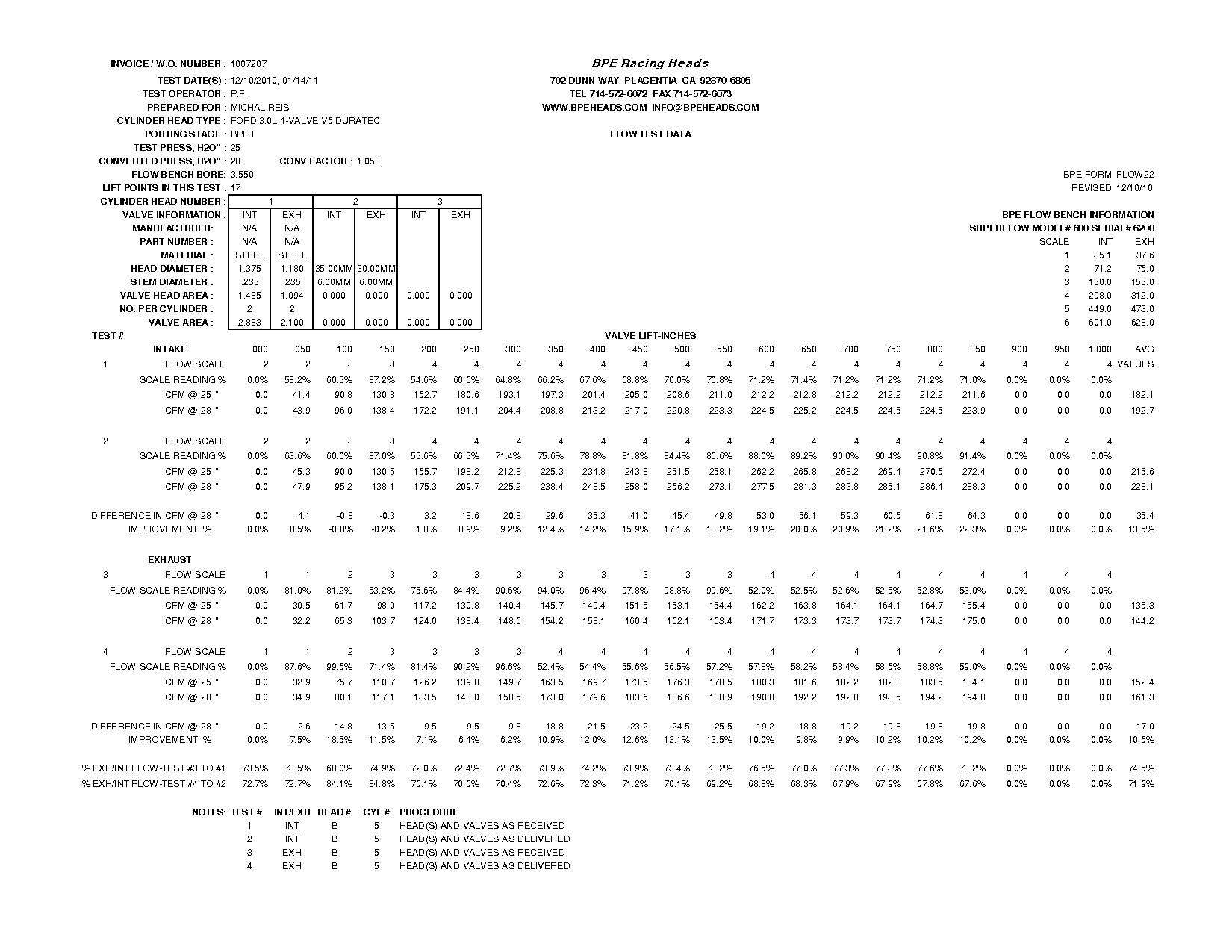

Before and After P&P flow test on one cylinder = $110

Before and After P&P flow test on all six cylinders = $210

BPE Racing says that historically after their port work a single cylinder flow test is very representative of all the cylinders and flow testing all of them is not really necessary.

So with that said do I spend the extra $100 to see all of the cylinder results or do I just pay $110 to see the results of one cylinder...

Thoughts?!

Before and After P&P flow test on one cylinder = $110

Before and After P&P flow test on all six cylinders = $210

BPE Racing says that historically after their port work a single cylinder flow test is very representative of all the cylinders and flow testing all of them is not really necessary.

So with that said do I spend the extra $100 to see all of the cylinder results or do I just pay $110 to see the results of one cylinder...

Thoughts?!