69Boss302

Has mile high skills

Since there is the continuos ongoing confusion regarding the altenator tabs and crank pulley and lack of pictures, I'm posting pictures and looking to solve my confusion as well.

Crank Pulley - 04 Taurus

This what I'm trying to do. Removing it by hand and as so many before me know, it is almost impossible.

So after trying this the results are beginning to round the hat looking piece that comes off the balancer.

Where does one cut the crank pulley? Please take my picture, draw on it where to cut and repost.

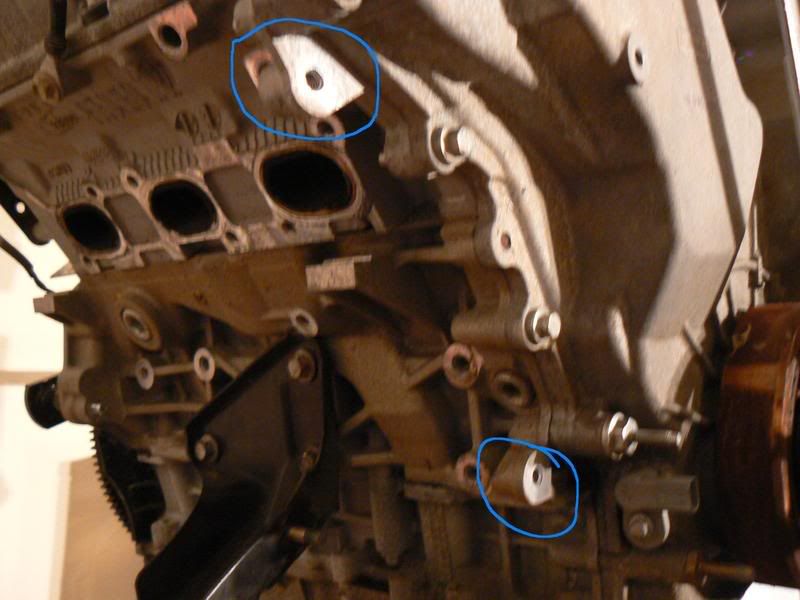

And now for the altenator tabs. This an 04 Taurus motor. I've placed the old bracket up against the new motor because "it will be obvious what needs to be cut." Well, it isn't to me. Mostly because when I put up the old bracket, the bottom mounting hole/dowel doesn't sit flush with the block. So what get's cut?

And then lastly for what I believe is the knock sensor. On this motor it is blocked off. Does it still go there in this position or am I one of the lucky ones that has to extend the wiring harness?

Crank Pulley - 04 Taurus

This what I'm trying to do. Removing it by hand and as so many before me know, it is almost impossible.

So after trying this the results are beginning to round the hat looking piece that comes off the balancer.

Where does one cut the crank pulley? Please take my picture, draw on it where to cut and repost.

And now for the altenator tabs. This an 04 Taurus motor. I've placed the old bracket up against the new motor because "it will be obvious what needs to be cut." Well, it isn't to me. Mostly because when I put up the old bracket, the bottom mounting hole/dowel doesn't sit flush with the block. So what get's cut?

And then lastly for what I believe is the knock sensor. On this motor it is blocked off. Does it still go there in this position or am I one of the lucky ones that has to extend the wiring harness?