|

|

|

|

Joined: Feb 2006

Posts: 6

Newbie

|

OP

Newbie

Joined: Feb 2006

Posts: 6 |

First, thanks for a great forum. I've already gleaned some valuable advice just from reading previous posts.

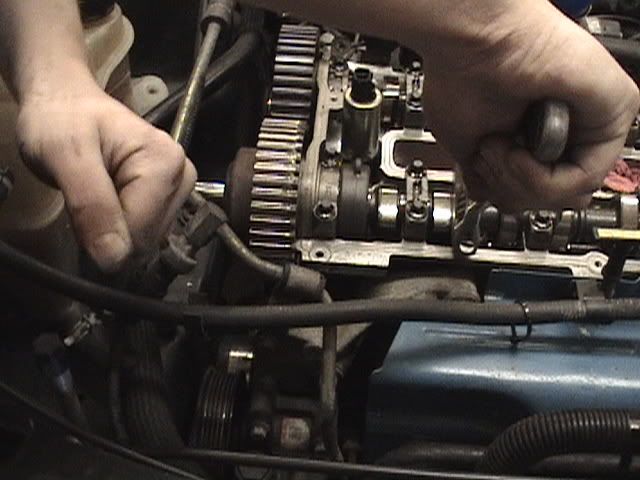

Last spring I had to replace the timing belt and timing belt tensioner on my 96' ford contour. It started off as a whistling noise when the engine was cold. This evolved into more of a grating noise accompanied with a taping on the timing belt cover. When I tore into the thing I discovered the timing belt tensioner was just barely functioning. The plastic pulley was cracked and the bearings were obviously shot.

Side note: I ruined the threads on the crankshaft trying to use a gear puller on the crank shaft pulley. It was just the entrance threads so I tried to force the bolt back in thinking that if I could get it started I would clean the threads up.

Well, this just resulted in ruining the threads on the bolt. I had to go buy a tap and re-tap the threads on the crankshaft. The new bolt is a little loose with the re-tapped threads, but I don't even want to think about replacing the crankshaft. I put a little silicone sealer on the back end of the bolt and tightened it down as much as I felt comfortable without stripping the threads out of the crankshaft. I marked the bolt and crankshaft pulley with a little paint and I check it every time I change the oil to make sure it hasn't slipped.

Beside the problems with the crankshaft pulley and bolt everything went pretty well. Found TDC, made sure the cams were lined up using the flat bar, put the new belt on. I was a little nervous about the timing belt tension. I loosened the timing belt tensioner bolt and let the spring pull tension on the belt. I then tightened it down a little and turned the crankshaft a few times. The belt seemed to have too much slack, and the slack region seemed to move as I turned the crank. I decided to just push the tensioner as taught as I could with my hand and tighten it down. Put everything back together and it seemed to run fine.

To get to the point - Things were fine for a few months. When it started to get cold outside I started noticing the tapping again on the timing belt cover. I thought maybe the tensioner bolt had come loose so I opened it back. Tensioner is still in place so I'm not sure why it is now loose. Does the timing belt stretch over the first couple months?

Anyway, after reading through a few posts on the board I think I am going to redo the timing and tension, but this time I'm going to loosen the cam bolts to let the sprockets turn freely while I adjust the tension. It is either this or really pry on the tensioner to put as much tension as I can on the belt. (Bad idea right?) Any thoughts? You think adjusting the tension with loosened cam sprockets might prevent it from loosening up again?

|

|

|

|

|

Joined: Aug 2001

Posts: 17,248

CEG road warrior

|

CEG road warrior

Joined: Aug 2001

Posts: 17,248 |

Unforutunately the timing belt is going to tap no matter what....there is a fix by putting washers with the bolts that hold the cover on to extend it a little so it doesn't tap.

Hector

2003 Rally Red Mitsubishi Evolution VIII

257HP/259TQ

2005 Lapis Blue Mazda 6s

RET: 00 Cabernet Red Ford Contour Zetec ATX SUPERCHARGED

160HP/141TQ

|

|

|

|

|

Joined: Mar 2002

Posts: 281

CEG\'er

|

CEG\'er

Joined: Mar 2002

Posts: 281 |

Some people swear by removing the timing belt and not loosening the camshaft sprockets at all, and this method works just fine for them and they are able to get the belt off and back on again perfectly the same as it was before.

For me, (and it may have been due to not having the proper Ford alignment tool to start the job out with), I just could not get the slack out of the belt between the pullies. After breaking the cam sprockets loose I was able to get it tensioned perfectly and I completely eliminated the slack in between the top pullies.

I think your plan to pull it back apart and re-tension with the sprockets loose is the way to go. Just so you know I have no tap tapping of the belt going on in my '96.

Make sure you have a good breaker bar of some sort for those sprocket bolts. I had to grab about a 2 foot length of metal pipe and slide it over my socket wrench (sorry socket wrench) to crack those things loose. To make things even more fun, I think they are Torx bolts, so take your time and make sure you have the proper tools for the job. I'm sure you already know this, too, but make sure to use a camshaft sprocket holding tool and not the alignment tool or timing belt to hold the sprocket while you loosen/tighten the bolts.

Good luck!

96 Contour GL 2.0L MTX with Early SE 7 spoke wheels, SE sideskirts, Koni Sport Kit

70 Mustang Sportsroof with mild 351W and '01 Mustang GT wheels

|

|

|

|

|

Joined: May 2002

Posts: 21,653

I have no life

|

I have no life

Joined: May 2002

Posts: 21,653 |

I tensioned by belt fine without breaking the cam gear bolts loose.

Did you use the spring and post (I think that's what it was) required for setting the tension on pre98 tensioners?

98.5 SVT

91 Escort GT (almost sold)

96 ATX Zetec (i brake to watch you swerve)

FS: SVT rear sway bar

WTB: Very cheap beater

CEG Dragon Run - October 13-15

|

|

|

|

|

Joined: Sep 2004

Posts: 498

CEG\'er

|

CEG\'er

Joined: Sep 2004

Posts: 498 |

I never had to loosen cam gears either, and I have no tapping.

96' ATX Zetec- stock

96' ATX Zetec- Modded

Kenwood KDC-319

5.75"-2 MTX 12's

Roady XT

Custom door panels

Mystique Cluster/oil pressure

Getting repainted(in primer)

Pre98 Lip

SE skirts

Mystique front lip

dingless

badgeless

|

|

|

|

|

Joined: Feb 2006

Posts: 6

Newbie

|

OP

Newbie

Joined: Feb 2006

Posts: 6 |

The first time around I did use the spring and post to try to set the tension. The tension seemed way too loose to me, and I ended up pushing the tensioner as tight as I could with my hand before tightening the tensioner bolt. I was concerned if the belt wasn't tight enough it would skip and I would cause some major problems. Is that a concern for this engine? I have read some of the posts talking about a noninterfering(?) engine - something about how a broken timing belt won't damage the piston heads or valves.

Well, if redoing the tension doesn't fix the tapping I may have to go with the washers. I'm actually more concerned with the belt skipping than I am with the tapping.

I bought some flat bar today to try to make a cam sprocket holder, and I have a pipe to help break the bolts free. Hopefully, this will take care of my problem. I'll report back in a couple days and let you know how it turns out.

Thanks for the comments!

|

|

|

|

|

Joined: Feb 2006

Posts: 6

Newbie

|

OP

Newbie

Joined: Feb 2006

Posts: 6 |

Okay, I took off work a little early yesterday and worked on the car. The first time, I loosend the cam sprockets, set the tension, and then retightened the cam sprockets. Then I turned the crank through a few turns, and wouldn't you know it I had slack between the two sprockets. I started thinking I might have to use washers to lift the timing belt cover (suggested above), but I decided to try to tension the belt one last time. The second time I was really careful not to let the sprocket turn as I tightened the sprocket bolt. Not sure if this was the trick or I just got lucky, but the belt is nice and tight all the way around - no more slack between the sprockets. I put everything back together and took it for a drive. Sounds great! Runs great! No tapping. Let's see if it still sounds this good in a couple months.

|

|

|

|

|

Joined: Mar 2002

Posts: 281

CEG\'er

|

CEG\'er

Joined: Mar 2002

Posts: 281 |

That's awesome... way to go  Thanks for posting back with the update. I'm sure you'll probably be ok for another 100K !

96 Contour GL 2.0L MTX with Early SE 7 spoke wheels, SE sideskirts, Koni Sport Kit

70 Mustang Sportsroof with mild 351W and '01 Mustang GT wheels

|

|

|

|

|

Joined: Dec 2004

Posts: 508

Veteran CEG\'er

|

Veteran CEG\'er

Joined: Dec 2004

Posts: 508 |

Yes after letting the gears freewheel on the cam they have to be held in place, otherwise as you tighten the camgear bolt it will want to turn the gear about a degree or so in that direction. Haynes manual does show a simple holding tool that fits the openings of the gear to hold it in place. But then your trying to hold the gear, hold the cam with a wrench on the flat spot, and tighten the camgear bolt at the sametime... Friends come-into play. But glad to hear it's working! Ah, can't wait for 160k lol

JD a.k.a Fingers

"Don't Panic"

'98 Contour GL 2.0L VCT ATX 88k

'98 Contour LX 2.5L MTX 120k

Street racing can kill

just less of a chance with a 2.0

|

|

|

|

|

|

|