lovemycountour

Be Gentle I'm New Here

- Joined

- Feb 7, 2007

- Messages

- 3

Hi,

I'd first like to thank all of you who've helped me with my car. This forum has answered a lot of my questions - even though I just finally got around to joining. This is going to be long. but feel free to skip to the end if you're just interested in the question...

My Contour is a 99 SE, 2.0 Zetec w/ 5-speed. It's utterly stock, and has been the most reliable car that I've ever owned. It has 186K on it, and has had only routine maintenance on it during that time - with the exception of an alternator replacement at 85K. The engine had been running flawlessly until after I recently replaced the timing belt.

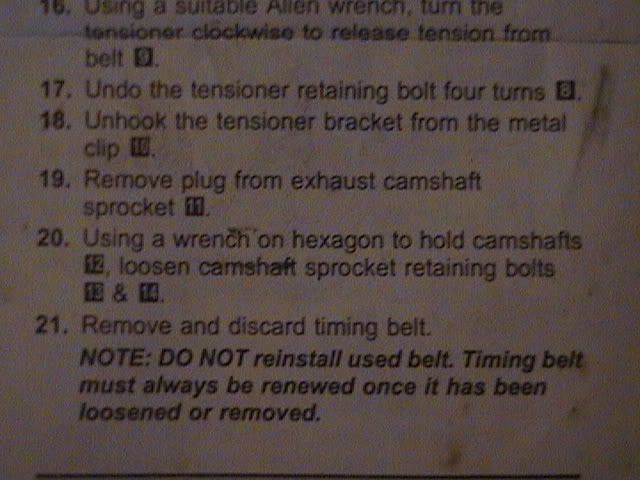

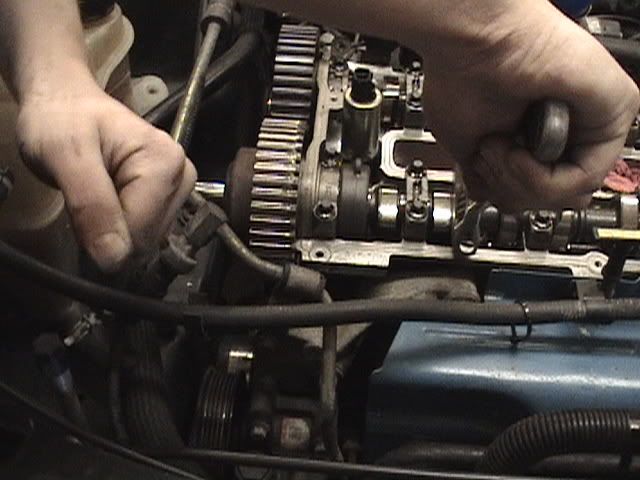

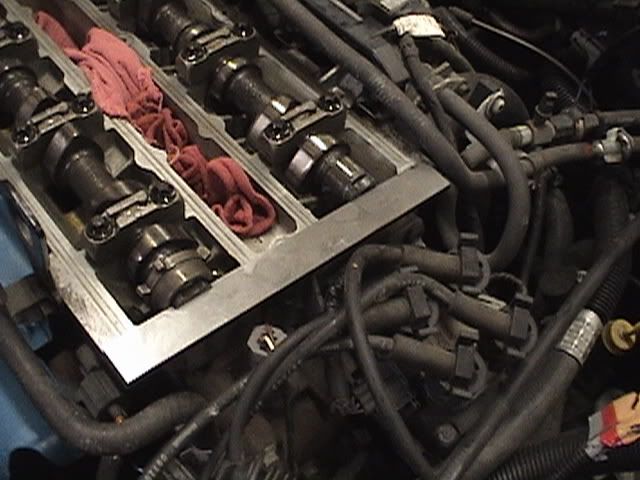

I purchased the requisite "timing kit", consisting of the flat metal plate to align the camshafts and threaded to align the crank. I followed the "revised procedure" that Ford put out in theirTSB.

The process was pretty routine - aside from some major grief getting the bolt on the harmonic balancer to come loose. When I put the engine back together again, though, it would not start. It acted as if it was getting little if any compression.

I checked the compression (not very precisely) and found roughly the following:

1 - 100 psi

2 - Neglegible

3 - Neglegible

4 - 150 PSI

This just about *had* to be a valve problem, so I took everything apart again and I went through the process one more time - trying to be extra careful. This time, I checked the compression *before* I put everything back together. The results were pretty much the same as before,

By now I was really scratching my head. With the special tools, there really didn't seem to be much of any way that I could set it up wrong. After all, putting the pin/plate in place were supposed to guaranty that I had everything set up correctly. The only way that it could get messed up was if that assumption was wrong.

I had been relying on the combination of the mark on the harmonic balancer and the insertion of the pin to know that I had the engine at TDC on #1. To check this, i used the old trick of sticking something in the spark plug hole on #1 and visually checking when it got to the highest point.

What I found was that TDC was *not* where I had thought it was! I put the pin into the side of the block, and it went in just fine here as well.

What I learned was this:

1) There was more than one mark for aligning the harmonic balancer. The on that I used was *not* the one that I should have used.

2) Contrary to what the instructions imply, the alignment pin will fully insert in locations *other* than a TDC! It works as a "stop" at the correct location, i.e. you can't get the engine to turn any further than TDC, but you *CAN* fully insert the pin quite a bit further back than that. A FULLY INSERTED PIN DOES NOT GUARANTY THAT YOU'RE AT TDC!

I seem to have set up the engine with the crank roughly about 7 degrees before TDC on the previous attempts. I suspect that I may have bent the valves on at least cylinders 2 and 3 while set up that way, but there was no noise, etc. to indicate that this might have happened.

Has anyone had bent valves on a Zetec? It's supposed to be an interference engine, but I've read a number of accounts of people fixing engines after a timing belt/idler failure on these. None of these mentioned valve damage, so I'm a bit puzzled.

I'd love to hear from anyone who can give me alternate explanation for what I'm seeing, but bent valves is my best guess at this point.

Thanks.

I'd first like to thank all of you who've helped me with my car. This forum has answered a lot of my questions - even though I just finally got around to joining. This is going to be long. but feel free to skip to the end if you're just interested in the question...

My Contour is a 99 SE, 2.0 Zetec w/ 5-speed. It's utterly stock, and has been the most reliable car that I've ever owned. It has 186K on it, and has had only routine maintenance on it during that time - with the exception of an alternator replacement at 85K. The engine had been running flawlessly until after I recently replaced the timing belt.

I purchased the requisite "timing kit", consisting of the flat metal plate to align the camshafts and threaded to align the crank. I followed the "revised procedure" that Ford put out in theirTSB.

The process was pretty routine - aside from some major grief getting the bolt on the harmonic balancer to come loose. When I put the engine back together again, though, it would not start. It acted as if it was getting little if any compression.

I checked the compression (not very precisely) and found roughly the following:

1 - 100 psi

2 - Neglegible

3 - Neglegible

4 - 150 PSI

This just about *had* to be a valve problem, so I took everything apart again and I went through the process one more time - trying to be extra careful. This time, I checked the compression *before* I put everything back together. The results were pretty much the same as before,

By now I was really scratching my head. With the special tools, there really didn't seem to be much of any way that I could set it up wrong. After all, putting the pin/plate in place were supposed to guaranty that I had everything set up correctly. The only way that it could get messed up was if that assumption was wrong.

I had been relying on the combination of the mark on the harmonic balancer and the insertion of the pin to know that I had the engine at TDC on #1. To check this, i used the old trick of sticking something in the spark plug hole on #1 and visually checking when it got to the highest point.

What I found was that TDC was *not* where I had thought it was! I put the pin into the side of the block, and it went in just fine here as well.

What I learned was this:

1) There was more than one mark for aligning the harmonic balancer. The on that I used was *not* the one that I should have used.

2) Contrary to what the instructions imply, the alignment pin will fully insert in locations *other* than a TDC! It works as a "stop" at the correct location, i.e. you can't get the engine to turn any further than TDC, but you *CAN* fully insert the pin quite a bit further back than that. A FULLY INSERTED PIN DOES NOT GUARANTY THAT YOU'RE AT TDC!

I seem to have set up the engine with the crank roughly about 7 degrees before TDC on the previous attempts. I suspect that I may have bent the valves on at least cylinders 2 and 3 while set up that way, but there was no noise, etc. to indicate that this might have happened.

Has anyone had bent valves on a Zetec? It's supposed to be an interference engine, but I've read a number of accounts of people fixing engines after a timing belt/idler failure on these. None of these mentioned valve damage, so I'm a bit puzzled.

I'd love to hear from anyone who can give me alternate explanation for what I'm seeing, but bent valves is my best guess at this point.

Thanks.