CSVT#49

Addicted CEG'er

Alright guys so I finally installed the turbo piping in my car and I'm a little concerned with some clearances.

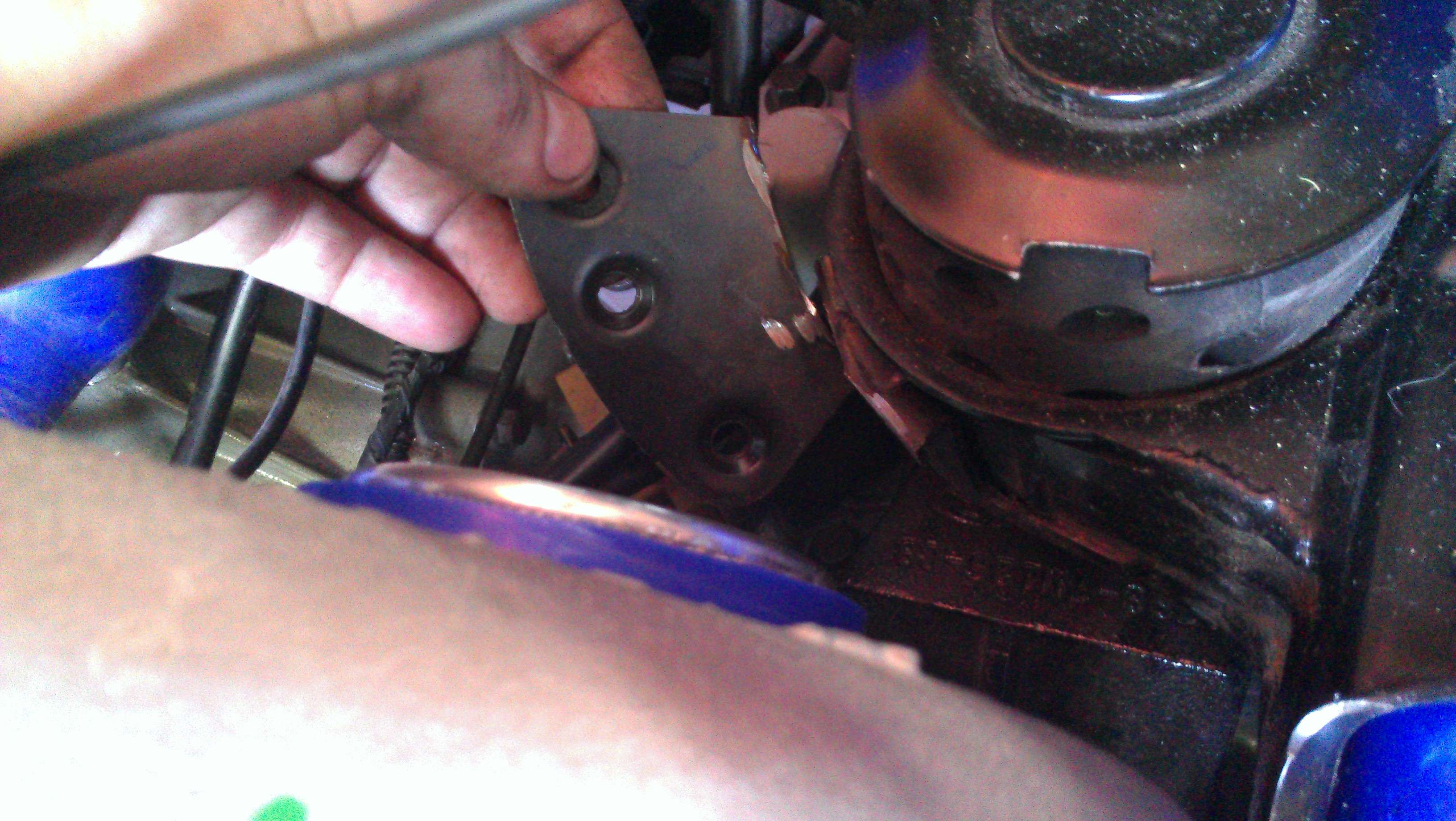

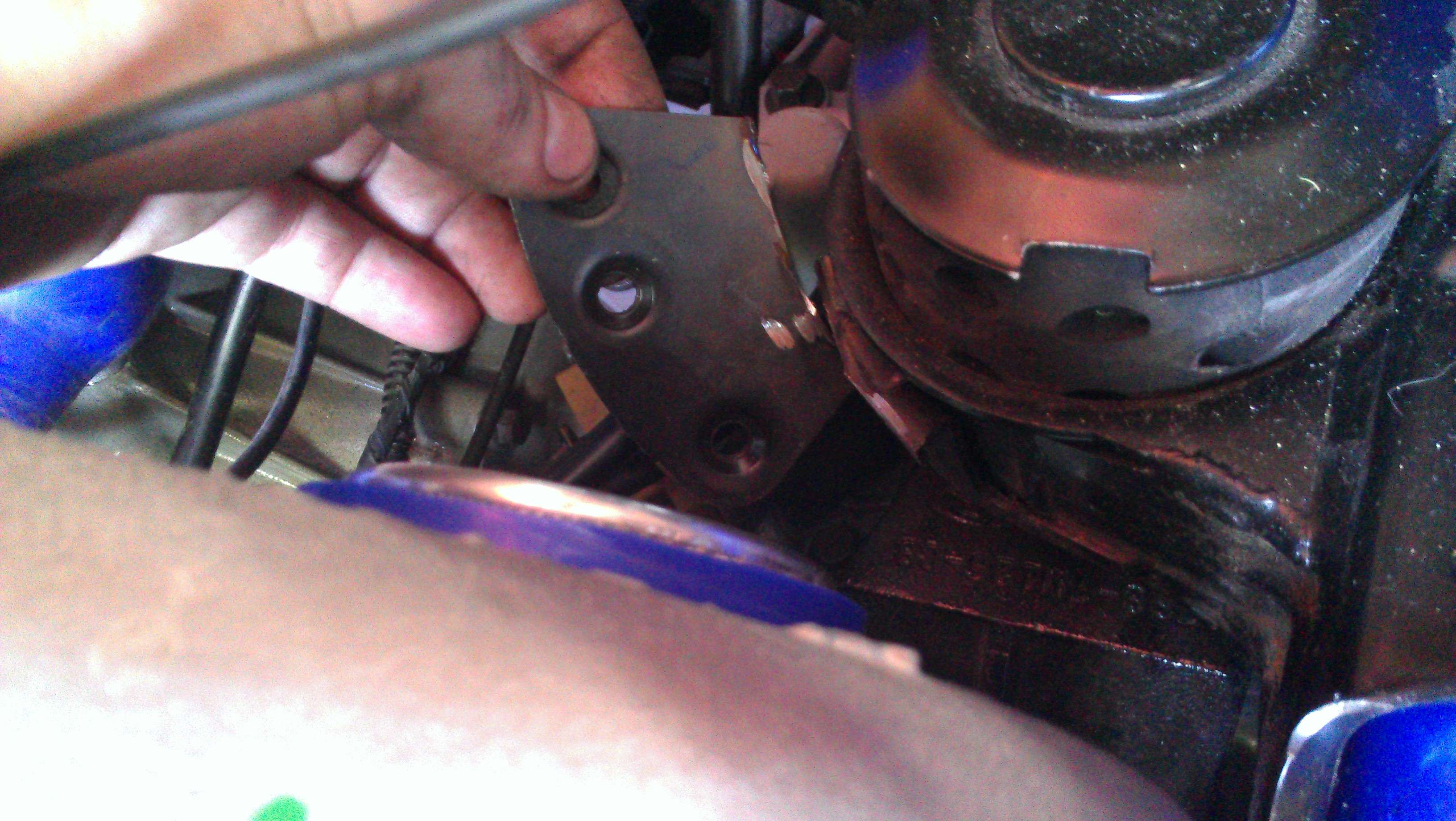

First one was the trans side mount. I had to cut the bracket off that was previously used to support the air cleaner. See first pic below. This isn't a huge deal as I won't need it again anyway. However it's going to be awful close for the inlet piping to get through there and hook up to the turbo.

Second one is the one I'm most worried about. The down pipe is touching the A/C accumulator. My car is going to have working A/C system so I don't want anything causing problems with it. I looked back at Brapple's install and Tuftour's install and it seemed as if Tuftour had about the same clearance as I do. Then looking at Brapple's install it seemed to have the turbo a lot further away from the driver side frame rail than mine, which in turn seemed to give better clearance to the accumulator.

I have the y-pipe pulled in every direction to try an maximize clearance, but can't seem to get anything more out of it. One thing I noticed on Brapple's piping was that the flange that connected to the header was larger, which looks like it pulled it away further. This would have effectively pulled the turbo towards the passenger side assuming the rear header connection. Pictures of their installs are also below for comparison.

Brapple

TUFTOUR

First one was the trans side mount. I had to cut the bracket off that was previously used to support the air cleaner. See first pic below. This isn't a huge deal as I won't need it again anyway. However it's going to be awful close for the inlet piping to get through there and hook up to the turbo.

Second one is the one I'm most worried about. The down pipe is touching the A/C accumulator. My car is going to have working A/C system so I don't want anything causing problems with it. I looked back at Brapple's install and Tuftour's install and it seemed as if Tuftour had about the same clearance as I do. Then looking at Brapple's install it seemed to have the turbo a lot further away from the driver side frame rail than mine, which in turn seemed to give better clearance to the accumulator.

I have the y-pipe pulled in every direction to try an maximize clearance, but can't seem to get anything more out of it. One thing I noticed on Brapple's piping was that the flange that connected to the header was larger, which looks like it pulled it away further. This would have effectively pulled the turbo towards the passenger side assuming the rear header connection. Pictures of their installs are also below for comparison.

Brapple

TUFTOUR