-

Welcome to the Contour Enthusiasts Group, the best resource for the Ford Contour and Mercury Mystique.

You can register to join the community.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

#49's new powerplant has arrived, let the build begin

- Thread starter CSVT#49

- Start date

79mustang351w

Hard-core CEG'er

^^This guy has jokes.

10% underdrive aint worth the price tag. But...I guess its more for having a quality damper on such a high dollar motor....to keep zee RODS in zee motaa.

10% underdrive aint worth the price tag. But...I guess its more for having a quality damper on such a high dollar motor....to keep zee RODS in zee motaa.

Pole120

Addicted CEG'er

^^This guy has jokes.

10% underdrive aint worth the price tag. But...I guess its more for having a quality damper on such a high dollar motor....to keep zee RODS in zee motaa.

That would be why I wanted one, but not if it's going to take away zee boost.

CSVT#49

Addicted CEG'er

Just so everyone knows, I did not buy the pulley for the underdrive. I bought it for the fact that it is fluid balanced and comes with an SFI certified certificate. The damper is capable of balancing the engine up to 18,000 RPM. I couldn't get my hands on a new dual damper so I bought this, which will perform better anyway. Unfortunately it came with a higher price tag, which is why I took so long to buy it as I searched for the best price. However since I took so long to buy it the going rate of the stupid thing went up. The lowest price used to be $318 +shipping, which now is $336+shipping.

Pole120

Addicted CEG'er

Just so everyone knows, I did not buy the pulley for the underdrive. I bought it for the fact that it is fluid balanced and comes with an SFI certified certificate. The damper is capable of balancing the engine up to 18,000 RPM. I couldn't get my hands on a new dual damper so I bought this, which will perform better anyway. Unfortunately it came with a higher price tag, which is why I took so long to buy it as I searched for the best price. However since I took so long to buy it the going rate of the stupid thing went up. The lowest price used to be $318 +shipping, which now is $336+shipping.

Figured. Same reason I would have taken one.

CSVT#49

Addicted CEG'er

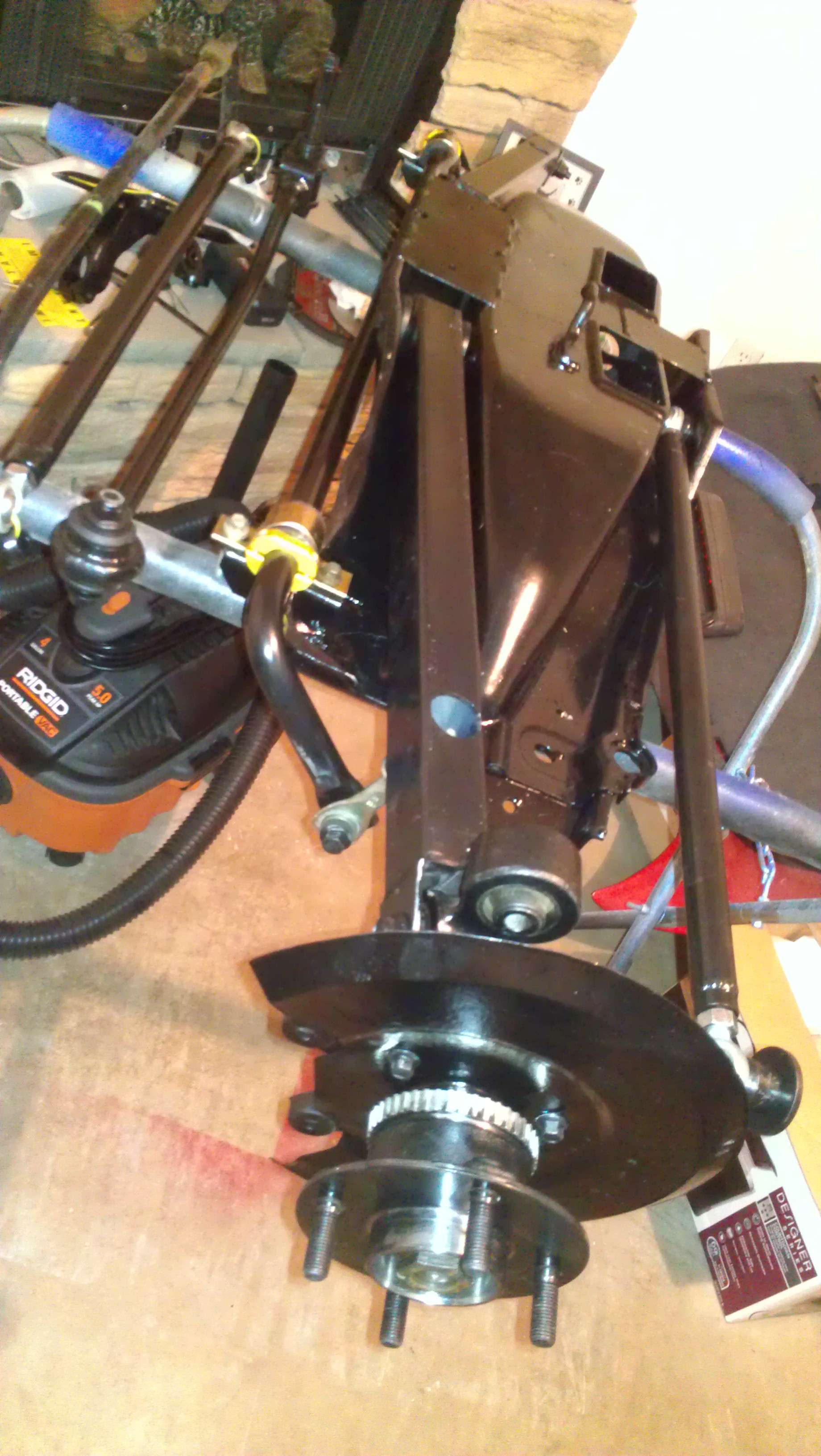

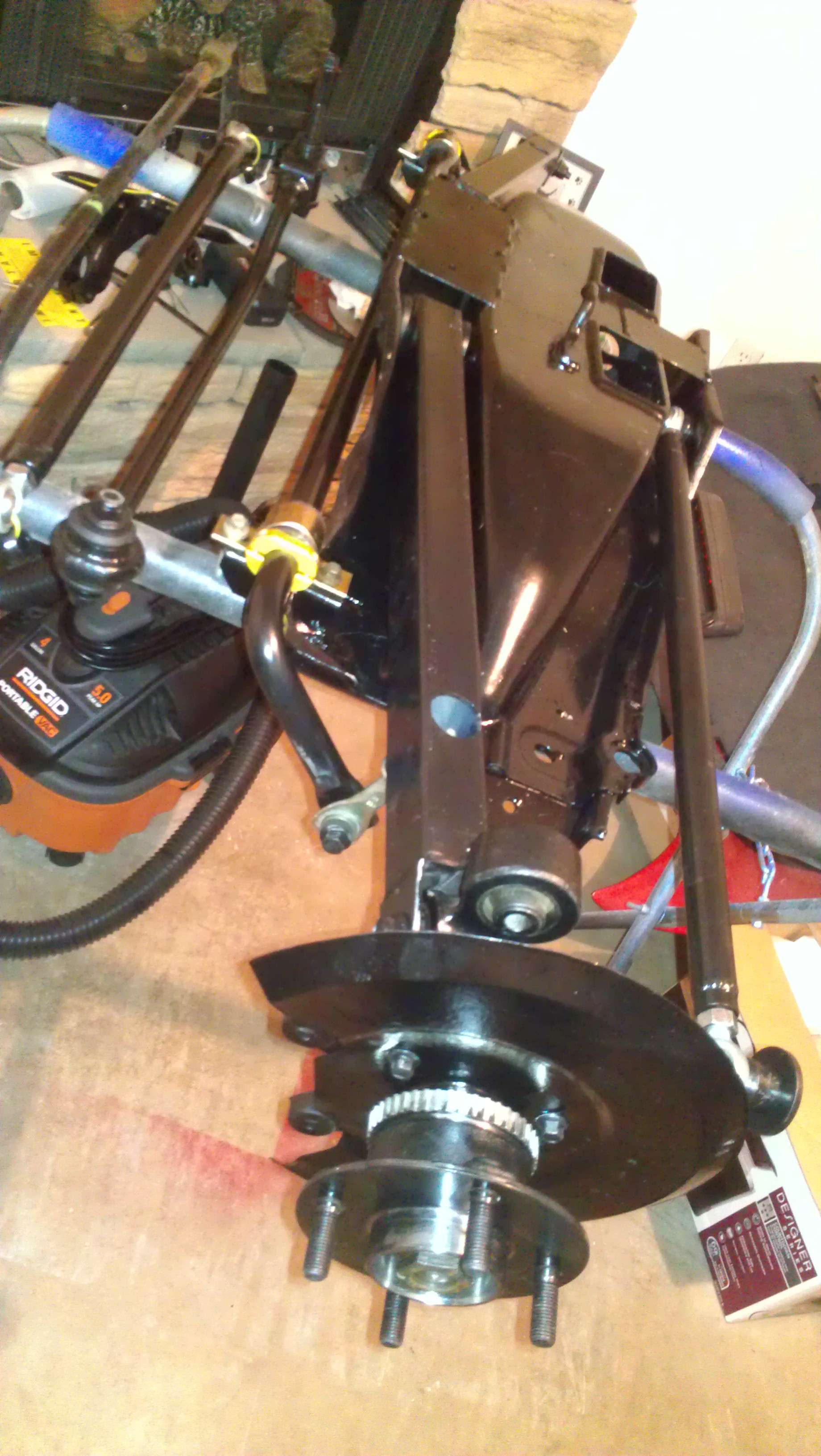

Should have my rear frame finally assembled soon. I've been spending a lot of time screwing around with sand blasting all of the hardware on it. A lot of the fasteners were rusted bad, and new hardware was just going to do the same thing long term and OEM flange head bolts could not be had at the hardware store (didn't have long enough bolts). So I've been spending a lot of flipping time cleaning and applying POR15 to all of the heads and shanks of the bolts to prevent the rust from returning. I have half of the subframe assembled, but just recently obtained new rear hub assemblies so I haven't gotten around to assembling the spindle assembly to the arms. Also took apart my brake booster and blasted and sealed he two halfs as it was looking bad too. With that here are some pics...

blu_fuz

New Member Classroom vulture

Didn't powdercoat the hardware? Lol

CSVT#49

Addicted CEG'er

Didn't powdercoat the hardware? Lol

POR15 will do a better job of preventing it from rusting again. That's my main concern.

i hope you coat the threads up good with neverseize or something to prevent them from rusting. this also will really throw your torque specs off. you should have zinc coated them. sandblasting hardware is usually not a great idea.

CSVT#49

Addicted CEG'er

i hope you coat the threads up good with neverseize or something to prevent them from rusting. this also will really throw your torque specs off. you should have zinc coated them. sandblasting hardware is usually not a great idea.

Any hardware that will have exposed threads will have zinc coating. Hardware that is not exposed will have antiseize applied.

Any hardware that will have exposed threads will have zinc coating. Hardware that is not exposed will have antiseize applied.

so are you going to use the factory torque specs? most of those are for dry threads. with antiseize you probably should drop your torques a bit.

CSVT#49

Addicted CEG'er

so are you going to use the factory torque specs? most of those are for dry threads. with antiseize you probably should drop your torques a bit.

I will be following the SAE J1701M standard with respect to antiseize application.

After all this you are going to reuse all the nuts and bolts??? If you send me one of everything you need and a list of how many I can ship you a package with everything you need brand new for probably like 20-30$

A lot of the hardware is not available from Ford. There is nothing wrong with reusing these nuts and bolts :shrug: No need to get all crazy about it. It's not like they were TTY bolts or anything. If I had to source all of the hardware I would want the exact same flange head bolts and nuts, and honestly it isn't worth the time and effort. For me to measure everything and determine the right hardware and then order it... frankly would have taken more time then it was for me to blast and recoat the fasteners that I have.

CSVT#49

Addicted CEG'er

Got the hubs coated and assembled the one to a spindle. Also put on one of the rotors I picked up to match my Baer track plus kit. Very nice

SVTbuckeye11

CEG'er

:drool:

wish I would have coated my spindles when I did my front end

wish I would have coated my spindles when I did my front end

CSVT#49

Addicted CEG'er

Getting there...

solo92s10

Hard-core CEG'er

Looks great. But why arent you putting the energy suspension bushing in the control arm?

CSVT#49

Addicted CEG'er

Looks great. But why arent you putting the energy suspension bushing in the control arm?

I have them and I still may do it, but the mount that is in the spindle assembly is pretty solid and at the time I didn't want to mess with drilling it out.

blu_fuz

New Member Classroom vulture

Even in these non-close up pics, those knuckle bushings look great! :laugh:

Pole120

Addicted CEG'er

I have them and I still may do it, but the mount that is in the spindle assembly is pretty solid and at the time I didn't want to mess with drilling it out.

FWIW, if you have an air chisel it's a 5 minute job. The arms look great! May have to make some more....